Contact Your NewwaySMTC Representative Now! [email protected]

Electronic Thin Carrier Tapes Industry 2019-2025 Application Trends

In the world, the advent of surface mount technology has brought about a dramatic change in electronic products. Semiconductor manufacturers have begun to apply high speed surface mount technology and surface mount production lines have been integrated for a number of semiconductor applications. Most printed circuits are now almost all using this low-cost, high-productivity, precision PCB production technology. Surface mount technology’s widespread adoption promotes the development of the surface mount component, the original plug type component has been gradually replaced by the surface mount component. In addition, people to the hand computer, computer and other electronic products of small size, multi-functional requirements, promote the surface mount components towards high integration, miniaturization direction development.

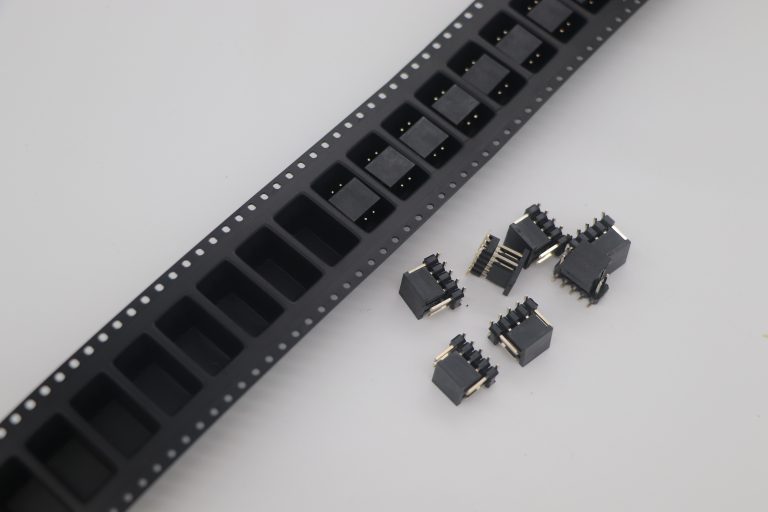

The thin carrier tape of electronic components is produced and developed with SMT.

The surface mount component in the production, the transportation, the packing and so on link all needs the carrier belt system, on the one hand is to protect the electronic component the protection role, on the other hand is to arrange the electronic component orderly on the surface mount machine carries on the high speed automatic packing, therefore from the protection, the economy, the capacity and so on aspect consideration, the carrier belt system has the advantage.The application of thin carrier tapes in smt can be seen in.

Overview of electronic components and their thin carriers

A thin carrier tape is a tape product used in the field of electronic packaging that has a specific thickness and is equidistant in the direction of its length.

Distributed with holes for carrying electronic components (also called pockets) and positioning holes for index positioning.

The advent of surface mount technology has brought significant changes to electronics

Thin carrier tape is mainly used in the electronic component mounting industry, which is used with tape or cover tape, resistor, capacitor, transistor. Diode and a series of electronic components are stored in the pocket of thin carrier tape, and form closed packaging by the matching tape or cover tape of thin carrier tape to protect the electronic components from pollution and damage during transportation. Installation of electronic components, tape or cover tape After the tape is peeled off, the automatic installation device removes and attaches the components in the pockets one by one through the precise positioning of the thin tape indexing holes. It is mounted on the printed circuit board to realize automation, high efficiency, high reliability and low cost security of chip electronic component loading and packaging.

Classification of thin carrier tape

There are more types and specifications of electronic components, and there are more specifications of thin strips to match them, and there are various classification methods according to different classification standards. There are mainly the following categories.

Thin carrier tape classification by width

According to the size of the electronic components packaged, thin tape is also divided into different widths. The common widths are 8mm, 12mm, 16mm, 24mm, 32mm, 44mm, 56mm, etc. With the development of high-precision and miniaturization of electronic components, the width of thin carrier tape is also getting narrower and narrower.

Thin carrier tape classification by function

In order to protect electronic components from electrostatic damage during transportation and packaging, some precision electronic components have clear requirements for the anti-static grade of the supporting thin carrier tape. According to the different anti-static grade, the thin carrier can be roughly divided into conductive, anti-static type (static dissipative) and insulating type.

Classification of thin type according to the molding characteristics of the cavity

According to the forming characteristics of the pocket, the thin tape can be divided into embossed tape and pressed tape. Embossed tape refers to the use of mold embossing or blistering methods to stretch the local material of the tape to form a concave pocket, this kind of tape can be formed according to the specific needs of different sizes of pockets to accommodate the size of electronic components; stamping tape refers to the formation of penetration or semi-penetration pockets by die-cutting. The thickness of electronic components that can be accommodated by this kind of tape is limited by the thickness of the tape itself, and can only be used to package components with thin thickness.

Classification of thin carrier tapes by material of thin tapes

According to the material of the thin carrier tape, it can be roughly divided into two categories, including paper carrier tape and plastic carrier tape. Plastic carrier tape can be further divided into PC (polycarbonate) carrier tape, PS (polystyrene) carrier tape and ABS (acrylonitrile-butadiene-styrene copolymer) carrier tape, and a small amount of PET (polyethylene terephthalate) and APET (amorphous polyethylene terephthalate) carrier tape.

Classification of thin carrier tapes according to the forming method of thin tapes

According to the forming method of thin tape, it can be broadly classified into intermittent type and continuous type. Compared with the intermittent type, the continuous molding method has better dimensional stability and higher dimensional accuracy; intermittent molding is more suitable for larger size pockets.

Application range of thin carrier tape

Thin carrier tape is mainly used for surface mounting of downstream electronic components, and can be widely used for IC, resistors, inductors, capacitors, connectors, fuses, switches, relays, connector plugs, oscillators, two or three channels and other electronic components. With the downstream electronic components type, quantity and performance of the continuous upgrade and optimization, thin tape system supporting the use of continuous development and innovation.

Electronic components thin tape, according to the use of raw materials, mainly divided into paper carrier tape and plastic carrier tape. Paper carrier tape has the characteristics of low price, easy recycling, etc., will be favored by electronic component manufacturers. It is mainly used for the packaging of electronic components with thickness less than 1mm. When the thickness of electronic components exceeds 1mm, plastic tape is generally used for packaging due to bending conditions and thickness restrictions.