Contact Your NewwaySMTC Representative Now! [email protected]

Development of electronic thin tape industry in China

Industry authority and supervision system

The National Development and Reform Commission (NDRC) guides and supervises the investment in the electronic component thin carrier industry, promotes the adjustment of industrial structure, and guides and improves the development of products and technologies in the industry through industrial policies.

The Department of Electronic Information of the Ministry of Industry and Information Technology is responsible for the industry administration of electronic information product manufacturing. To organize and coordinate the development and production of major system equipment, microelectronics, and other basic products, and to organize and coordinate the production of supporting equipment, components, instruments, and materials required for national major engineering projects; Promote the spread and application of electronic information technology. China Electronic Components Industry Association is a non-profit social organization formed voluntarily by enterprises (public institutions) in the electronic components industry. Its main responsibilities are: to play the role of bridge between government departments and enterprises (public institutions); Carry out industry research; Strengthen industry self-discipline; Fulfill the purpose of serving enterprises; To provide technical, economic, management, market, and other consulting services; To organize the training of personnel, technology, management, and regulations; Help enterprises to expand the market; To organize the work of new product appraisal, evaluation of scientific research achievements, the establishment of industry standards and quality supervision with the approval of relevant government departments.

Technical level and characteristics of the industry

Antistatic technology

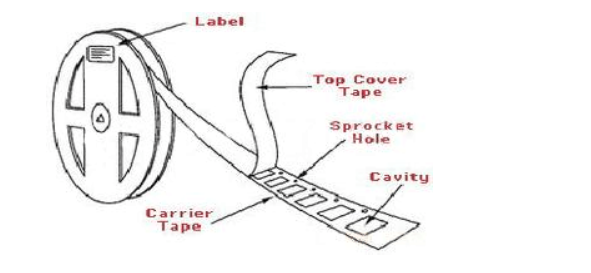

In the process of surface mounting electronic components with thin carrier tape, anti-static technology is an important technology that affects the stability of mounting. Plastic tape is more prone to static electricity than paper tape. Generally speaking, electronic components are sensitive to static electricity, and the existence of static electricity will make electronic components be absorbed by static electricity and break away from the carrier hole in the surface mounting process, thus affecting the normal mounting process. Therefore, a good thin carrier is often inseparable from a perfect anti-static treatment technology.

Stripping force technique

Stripping force refers to the pull force required under specific conditions and certain stripping Angle and stripping speed in order to separate the surface material and the substrate coated with a certain medium. In the process of surface mounting, the stripping of tape or cover tape on the surface of a thin carrier belt and the capture of electronic components are carried out synchronously and at a high speed, and the two need to cooperate to achieve a better effect of mounting. Taking paper tape as an example, if the peeling force is large, the electronic components are prone to vibration and break away from the tape hole in the process of surface mounting. If the peeling force is small, the upper tape will be peeled off in advance, so that the electronic components waiting for mounting lose the packaging protection of the upper tape. Therefore, appropriate stripping force plays an important role in the packaging effect.

Performance stability

The stability of packaging material in surface mount is an important performance index. Surface mounting technology has the characteristics of large-scale, mass, standardization, rapid, etc. The whole mounting process is assembly line continuous production, the general SMT machine processes about 60,000~120,000 pieces of electronic components per hour, so the good stability of thin loading tape can effectively ensure the effective qualified rate of surface mounting finished products. Improve the production efficiency of the whole assembly line.

Base paper production technology

Paper carrier is an important kind of thin carrier of electronic components, one of the important core technology is the production process of base paper, the product performance of base paper has a great influence on the use effect of the thin paper carrier. The thickness, water resistance, interlayer bonding, and burr treatment ability of base paper have important an influence on the processing efficiency and quality of the back end.

The specific technical features are as follows:

(1) With good water resistance, in the process of external environment change, will not be affected with moisture thickening, or its range of change in a small fluctuation range.

(2) the thickness is uniform, the error is generally not more than 0.02mm, and the paper can not be spliced.

(3) With good interlayer binding force, repeated winding will not stratification.

(4) With good stiffness, to ensure normal operation in the process of use.

(5) After cutting the base paper, there should be good bonding and matching between the tape and the upper tape.

(6) The use of special beating technology and surface treatment technology, control the uniformity of grinding pulp and fiber length in a specific range, reduce the production of burr in the process of paper tape punching.

The production of base paper usually requires a long time of accumulation of technical foundation and cooperation with practice, and has a high technical threshold, which forms a certain barrier for new competitors to enter the industry.

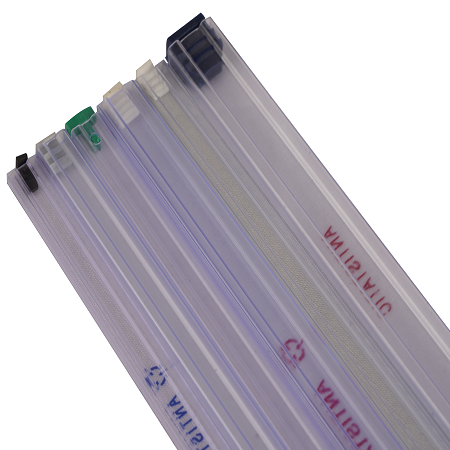

Business model of industry

The electronic thin carrier of this industry mainly serves for the surface mounting of downstream electronic components, and its product design, research and development, production and specifications of electronic components have a high correlation. Due to the variety of electronic components and different product performance is also different, so for its supporting use of the belt is also diverse.

To date, most enterprises in the industry production of thin loading class or a few products, in terms of paper loading, tape base paper production and processing and related mostly were completed by different companies, which makes the downstream of the electronic components production enterprises need for purchasing products from different enterprises and the mutual matching use, There may be cases where the base paper and tape do not match in performance parameters, leading to unnecessary debugging run-in. In contrast, enterprises with a certain scale and technological advantages in the forefront of the industry are committed to developing a variety of products with a wide range of coverage through technological accumulation and market analysis in the early stage. They are positioned to provide customers with complete overall solutions to improve the service level to customers.

In addition, by extending the industrial chain and controlling core raw materials, the quality of specific products can be guaranteed to a certain extent, while achieving the purpose of cost control. At present, only a few enterprises in the industry such as Jiemei Technology can integrate core raw materials and back-end precision processing to form competitive advantages in the whole industry chain.

The cyclical, regional, or seasonal nature of the industry

1. Periodicity

Electronic components and light-weight loaded with industry and it’s downstream of the electronic components industry and has a certain correlation between the terminal consumer electronics, due to the types of consumer electronics is relatively more, target customer group is relatively broad, its products, in general, do not have obvious periodicity, it also makes the electronic components and light-weight loading does not exist obvious cyclical industry. The development of the industry is affected by the change of a sub-industry downstream and the probability of significant adverse impact is relatively small, but the electronic components thin carrier industry is closely related to the development of the national economy and the improvement of people’s living standards, and there is a certain degree of correlation between the periodicity of the industry and the periodicity of the national economic development.

2. Regional

The regional characteristics of the industry are determined by comprehensive factors, such as whether the products of the enterprise have transportation restriction conditions, the distribution of downstream customers, and the requirements for the timeliness of the products. Generally speaking, as the downstream electronic components industry is mainly concentrated in Jiangsu, Guangdong, and other regions, the industry also has a certain regional. After years of development and industrial layout, domestic electronic components manufacturers downstream of the industry are regional, mainly concentrated in the electronic components manufacturing regions with more developed economies and better industrial infrastructure, such as the Pearl River Delta region, Yangtze River Delta region, etc. In recent years, with the development of China’s economy, the gap between the economic development of the central and western regions and the coastal regions has narrowed, and the electronic components industry in the central and western regions also shows a trend of vigorous development, which is also in line with the current situation of China’s regional economic development.

3. Seasonality

In general, the industry downstream consumer electronics seasonal weaker, but in some traditional festivals such as the Spring Festival, Christmas, etc., merchants would do some promotional activities, which makes the consumers in this period tend to increase their consumption, to make the shipments to increase consumer electronics, and drive the upstream product requirements. Therefore, the upstream electronic components industry of consumer electronics and electronic components of the thin strip industry, generally do not have obvious seasonality. But for different enterprises, due to the difference in product structure, it may show certain seasonality.

Correlation between the industry and upstream and downstream industries

The upstream of electronic components thin carrier enterprises are mainly wood pulp, plastic particles, and other materials production enterprises; The downstream application is wide, mainly for all kinds of electronic components manufacturing enterprises. The relationship between the industry and upstream and downstream is as shown in the figure below:

1. Relevance to the upstream industry

The upstream of this industry is mainly wood pulp, plastic particles, and other production enterprises. Among them, the wood pulp can be divided into broadleaf wood pulp and coniferous wood pulp according to different raw materials. The price change of wood pulp directly affects the production cost of the base paper. At present, China’s wood pulp mainly depends on imports, wood pulp prices maintain overall stability, but also have interval fluctuations.

There are more kinds of plastic particles, and the supply is relatively stable, partly dependent on imports.

As can be seen from the above, the price of polycarbonate decreased during the reporting period, mainly for plastic particles as petrochemical derivatives, and the price change depends on the market supply and demand system of its basic products.

2. Relevance to downstream industries

The industry is closely related to the development of the downstream industry, the downstream industry has a greater traction role in the development of the industry, and the downstream industry to the industry product demand directly determines the market demand of the industry. Electronic components thin carrier is mainly used in the downstream electronic components industry. China’s electronic components industry is mature and has become the world’s largest producer and exporter of electronic components. The production and market development of electronic components have entered a mature development stage. Due to the wide application of the downstream industry, the prosperity of the thin carrier industry of electronic components is relatively less affected by a single downstream industry and is closely related to the development of the whole macro real economy.