Contact Your NewwaySMTC Representative Now! [email protected]

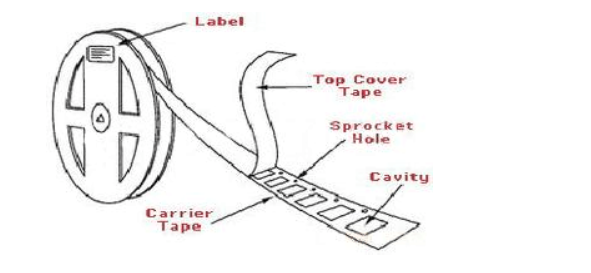

Carrier Tapes Forming Machine

Japan original Panasonic PLC programming control, Shanghai Eview stepping electrical man-machine interface; Japanese original Panasonic servo motor and driver, and NsK screw with pull belt, ensure P0 and P2 highly accurate;Taiwan solenoid valve and guide rod cylinder with forming heating stability, each component of the cylinder and more accurate induction control;

More and more mature electronic product design scientific, practical in recent years, and most electronic products involve Customized small quantity and variety. So in order to better meet the needs of customers and improve the competitiveness of the us, we have been planning to build factories around important customers.

The company began to design and develop the automatic production equipment for Carrier Tapes in 2011. At present, we provide 3 kinds of mature and stable standard machines and Several non-standard machines, which are carefully designed and developed by the ourselves, and have been continuously improved and optimized according to the actual quality control needs. For the process of quality stability and efficiency to provide the best guarantee.

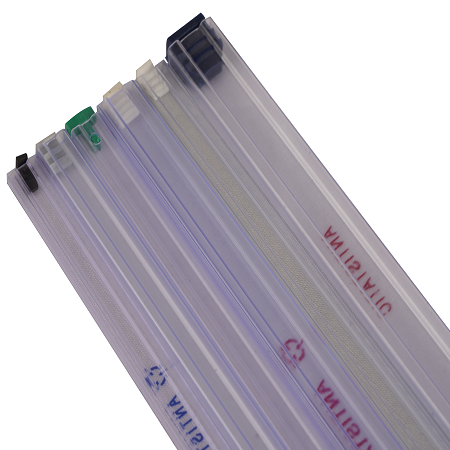

our products superior performance, precision size, excellent quality. We can customize different rules and shapes to match diversified electronic components, which can be customized for customers, fully meet the diversified needs of customers in a small amount, and truly achieve good quality, fast delivery and reasonable price. I look forward to serving you.

Carrier Tapes Forming Machine

Japan original Panasonic PLC programming control, Shanghai Eview stepping electrical man-machine interface;

Japanese original Panasonic servo motor and driver, and NSK screw with pull belt, ensure P0 and P2 are highly accurate;

Taiwan solenoid valve and guide rod cylinder with forming heating stability, each component of the cylinder and more accurate induction control;

Automatic alarm detection molding groove and P2 size, automatic feeding and receiving device, intelligent operation;

Full aluminum alloy frame, base plate mold base steel plated hard chrome, strong anti-scratch wear, beautiful and generous;

The heating module, forming module, and punching module are equipped with XY axis micro card, which can fine-tune the mold position and adjust the size accurately. The mold adjustment machine is fast, efficient, and easy to operate:

From the raw material transmission, heating, forming, punching, counting, cutting, to winding and receiving materials are integrated automatic completion;

Suitable for the molding of 12mm~88mm wide loads (above 88mm can be customized), the deepest KP 0 is 30mm;

Production capacity up to 300M/H;

Ac 220V power supply, working pressure 0.35~0.80MPa, rated power of the whole machine 2.5KW.