Contact Your NewwaySMTC Representative Now! [email protected]

Analysis of the causes of bad carrier tape and improvement measures

Newwaysmart in 18 years of carrier tape production experience, firm first-class production experience, summed up a lot of carrier tape production process problems and solution strategies and solutions, for customers to produce quality and quantity of products, creating a first-class customer experience.

In the production of carrier tapes in many companies there are such problems as jamming, to see Newwaysmart’s insights into the problem and solution strategies.

There are mainly two types of reasons for jamming: mainly the size of the parts is large, parts deformation or burrs and carrier tape size is small, deformation, barbs, poor molding and poorly considered design reasons, it will lead to jamming.

In the production of carrier tape bad cause analysis:

There are mainly two types of reasons for jamming: mainly the size of the parts is large, parts deformation or burrs and carrier tape size is small, deformation, barbs, poor molding and poorly considered design reasons, it will lead to jamming.

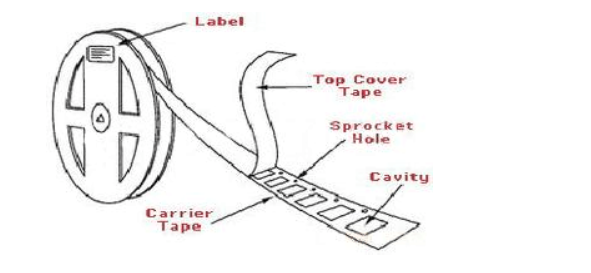

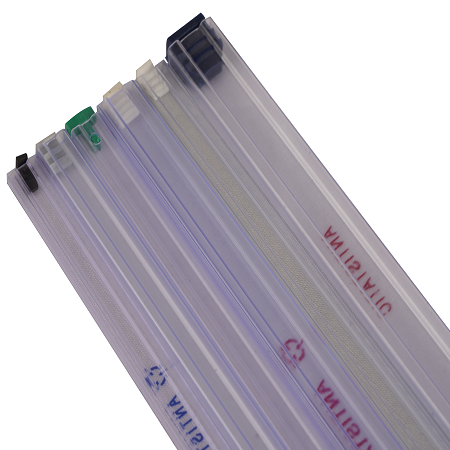

Carrier tape parts category

The size of the part is not within the design range, resulting in interference with the carrier tape slot, resulting in the phenomenon of jamming; or the existence of deformation or burr parts, deformation or burr position and interference between the carrier tape slot, resulting in jamming.

Carrier tape type

Forming die wear causes the size of the forming die to become smaller, resulting in interference between the carrier tape slot and the part, resulting in a jam.

For this problem we make the corresponding solution strategy and improvement countermeasures.

Carrier tape part Category

Ensure that our part dimensions are within the designed tolerances. Package parts are fully inspected before packaging to avoid deformation and burr of the parts.

Carrier tape category

We strictly require the engineering to strictly follow the “Mold Operation Management Procedures” to control the life of the mold, and regularly confirm the maintenance of the mold to ensure that such problems do not occur.

The producer should ensure that the discharge tray can smoothly discharge the material or the receiving tray can normally receive the material to avoid the phenomenon of misalignment of the heating die due to the pulling of the leather material.

What is our handling solution for carrier tape

We ask the technician to set the machine strictly according to the molding parameters on the SOP of the mold to avoid too thin in the slot and easy deformation. What is indispensable is to do a good job of carrier tape packaging protection and reduce express delivery as much as possible to avoid deformation of the carrier tape groove caused by transportation. Our engineers do design, need to understand the upper and lower limits of the client, better understanding of the customer to design the carrier tape groove cavity, to avoid the phenomenon of card parts.

Above we have some problems and improvement strategies for carrier tape jamming, specializing in and overcoming the various problems that arise, professional production of customer satisfaction products.