Contact Your NewwaySMTC Representative Now! [email protected]

New production methods for cover tape and their role in the market

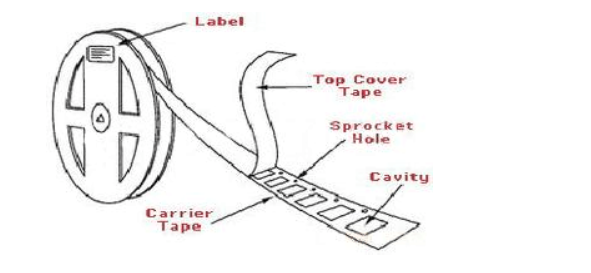

Cover tape is a tape product used in the field of electronic packaging, which is used in conjunction with carrier tape; the production of cover tape is mainly complementary to the carrier tape, forming a closed and sealed state, capable of protecting electronic components.

What is the production methods of cover tape?

Cover tapes are usually made of polyester or polypropylene film as a base layer and are laminated or coated with different functional layers, such as antistatic layer, adhesive layer, etc.

The production method of cover tape in the prior art requires the following steps

1. After the PET lamination, it is treated with 2 coats of glue and one coat of electrostatic agent

2. By PET lamination with one PET coating of electrostatic agent;

However, the biggest disadvantage of these production methods in the prior art is the long production cycle, half of the production cycle is more than 48h, at the same time, due to the long production cycle, it will also lead to its production process is cumbersome, the production of large inputs, production costs and other problems.

The solution to this kind of produced cover tape is to design a new kind of cover tape which includes a PET film layer, polyurethane glue layer, PE mixed layer, and glue layer. The cover tape structure is novel in structure design and easy to manufacture compared with other cover tape structures in the prior art; and through the method designed by the present invention, this method can replace imported products in actual production with its short whole production cycle, high efficiency, low cost, and excellent performance. This method in the application can greatly reduce the production cost and input costs of enterprises.

The production performance index requirements of cover tape

1. Peel force is the most important technical index of cover tape.

2. Optical performance indicators include haze, light transmittance and transparency.

3. The performance of surface resistance is required to reach 10E9-10E11.

4. Tensile performance indicators include tensile strength and elongation (tensile percentage). Tensile strength is the maximum stress that the sample can withstand before breaking.

The production performance index of cover tape is more able to guarantee the production quality of cover tape.

What is the role of cover tape in the market?

Cover tape is generally sealed on the surface of the carrier tape, by means of external force or heating, in order to form a closed space and protect the components in the carrier tape bag.

Cover tape adhesive force

Cover tape on the market is mainly through the adhesive force to control the size of the peeling force, but because the same adhesive with the surface material of different carrier tape when the size of the adhesive force will be different, and the adhesive force of the adhesive in different temperature environments and aging conditions will also change, coupled with the peeling of the residual adhesive pollution sometimes occurs.

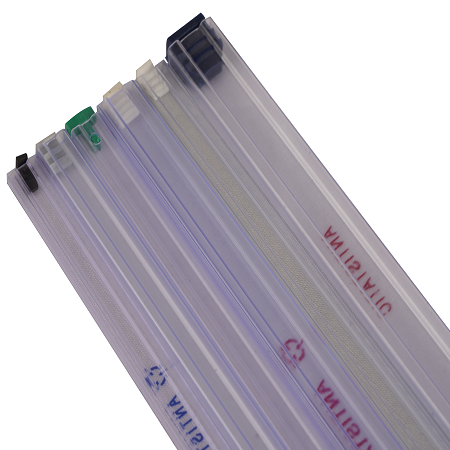

The new cover tape production technology is more conducive to avoiding electronic components’ electrostatic adsorption to the cover tape, the cover tape surface will usually have anti-static requirements. The level of anti-static is expressed in terms of surface resistance. The cover tape is generally required to have a surface resistance of 10E9-10E11. The carrier tape can also be formed into different representative pockets to suit the size of the electronic components to be contained by specific requirements. The role of cover tape is used together with the carrier tape, but also according to the specific size of the carrier tape on the market, made to fit the size of the bandwidth of the carrier tape size and its length, for the protection of electronic components from damage caused by static electricity.

The electronic product in the cover tape and the carrier tape protection role under the volume increasingly miniaturization, the function increasingly diversification, the component increasingly precision, semiconductor packaging and surface mount technology integration has become a general trend, will new technology will appear also will slowly occupy the market, provide to have the need of packaging technology products.