Contact Your NewwaySMTC Representative Now! DuncanLi@newwaysmart.com

One-stop SMT electronic components packaging plays an important role in the development of the industry

We are one of the one-stop service providers of thin carrier tape for electronic components packaging, with a comprehensive product range and a long-term commitment to research, development, and technological innovation of thin carrier tape for electronic components.

Surface assembled components can be provided to customers in four types of packaging

We have tape and reel packaging, stick packaging, tray packaging, and bulk packaging.

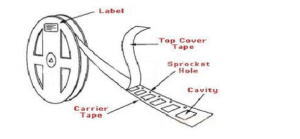

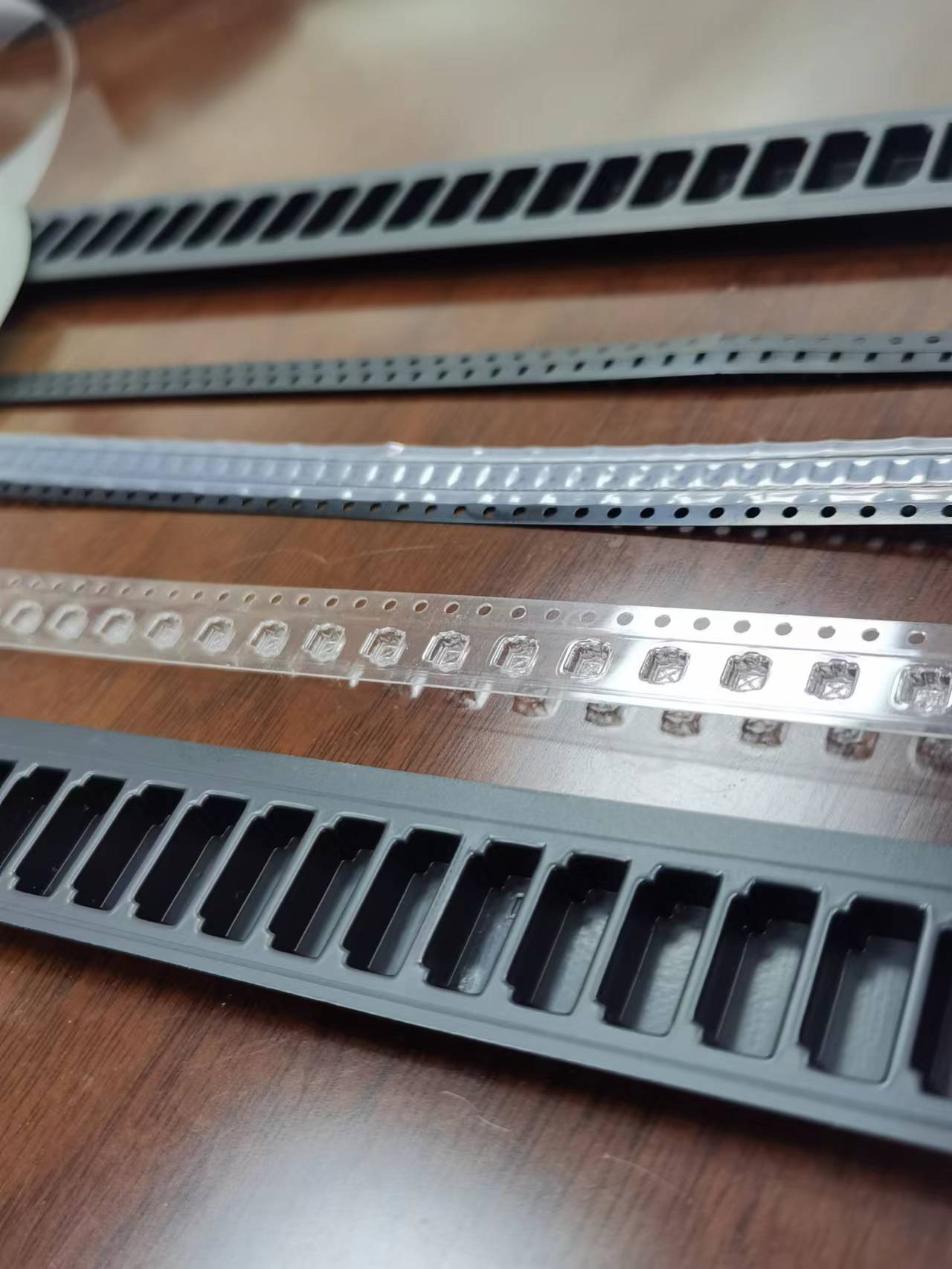

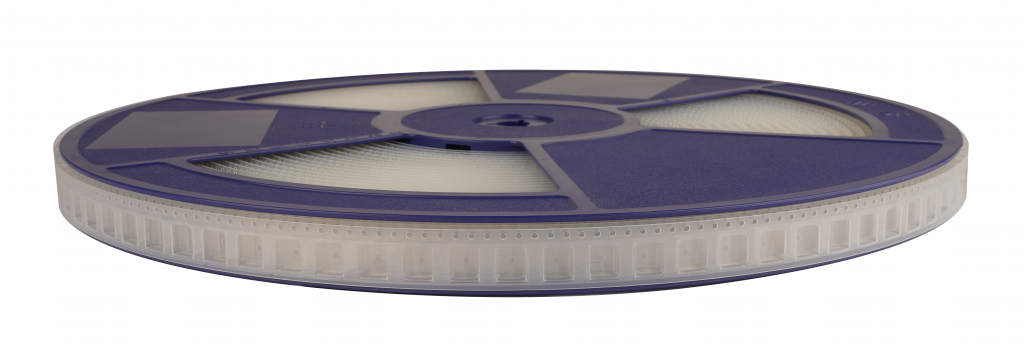

Tape and Reel

Tape and Reel packaging is the most widely used, the longest application time, adaptability, high placement efficiency of a packaging form, has been standardized. Except for QFP, LCCC, BGA and other large devices, the rest of the components can be used in this packaging form. The paper carrier tape is composed of a bottom belt, a carrier tape, a cover tape and a paper winding disk. The small round hole on the belt is the positioning hole, so that the feeder on the geardrive; tangular hole for the material cavity, components put on the winding on thematerial tray. The width of the paper tape is generally 8mm, the hole distance of the positioning hole is generally 4mm, less than 4mm series positioning hole distance is 2mm. Positioning hole spacing and component spacing according to the specific conditions of the components, generally a multiple of 4. When using paper carrier tape for componentpackaging, the required component thickness is about the same as the thickness of thepaper tape the paper carrier tape should not be too thick, otherwise the feeder can not be driven, therefore, the paper carrier tape is mainly used for packaging smaller rectangularchip components, such as chip resistors, chip capacitors, cylindrical diodes, etc.

Plastic Carrier Tape and paper carrier tape

Plastic Carrier Tape and paper carrier tape structure is roughly the same size, the difference is that the material box is convex. The plastic carrier tape can package some components which are slightly larger than the paper carrier tape, including rectangular, cylindrical, shaped SMCs and small SOPs, and the upper peeling device on the feeder removes the film cover tape before picking up the material.

Adhesive carrier tape

The bottom side of the tape, IC on the tape, and double-row hole drive, SMT placement processing, the feeder on the lower peeling device. Adhesive carrier tape is mainly used to package large size chip components, such as SOP, chip resistor network, etc.. Carrier tape packaging is the most common form of component packaging, SMD processing, carrier tape mounted on the feeder feed, the two match the bandwidth, that is, according to the bandwidth of the carrier tape to choose the feeder specifications, the common carrier tape bandwidth of 8mm, 12mm, 16mm, 24mm, 32mm, 44mm, 56mm, 72mm, etc..

Tube Packaging (Tube)

Tube Packaging (Tube) is mainly used for packaging rectangular, chip components and small SMD and certain shaped components, such as SOP, SOJ, PLCC and other integrated circuits, suitable for a variety of small batch of products. Rod packaging shape s a long tube with a rectangular inner cavity, packaging rectangular components; the inner cavity is shaped, used for packaging shaped components.

The Tray Packaging (Tray)

The Tray Packaging (Tray), also known as the waffle tray (Waffle), there is a single layer, up to more than 100 layers. Tray packaging is mainly used for the packaging of components with larger body shape or easier to damage pins, such as QFP, narrow pitch SOP, PLCC, BGA and other integrated circuits and other devices.

Bulk (In bulk) Pinless

Bulk (In bulk) Pinless, non-polarized surface assembly components can be bulked (Bulk), such as general rectangular and cylindrical capacitors and resistors. Bulk components are low cost, but are not conducive to pick and place on placement processing equipment.