Contact Your NewwaySMTC Representative Now! [email protected]

Storage requirements and precautions for electronic components

The life of electronic components of different quality is different, and the life also lies in how to use, if applied properly the life of electronic components in about 5-10 years. Resistors, inductors, capacitors, semiconductor devices (including diodes, transistors, field tubes, integrated circuits), that is, under the same operating conditions, semiconductor devices have the greatest chance of damage. According to the statistical reports of device physical failure data from several companies, there are cases of device failure induced by various stresses (electrical, mechanical, environmental, moisture sensitive, etc.).

Various electronic components warehouse storage requirements

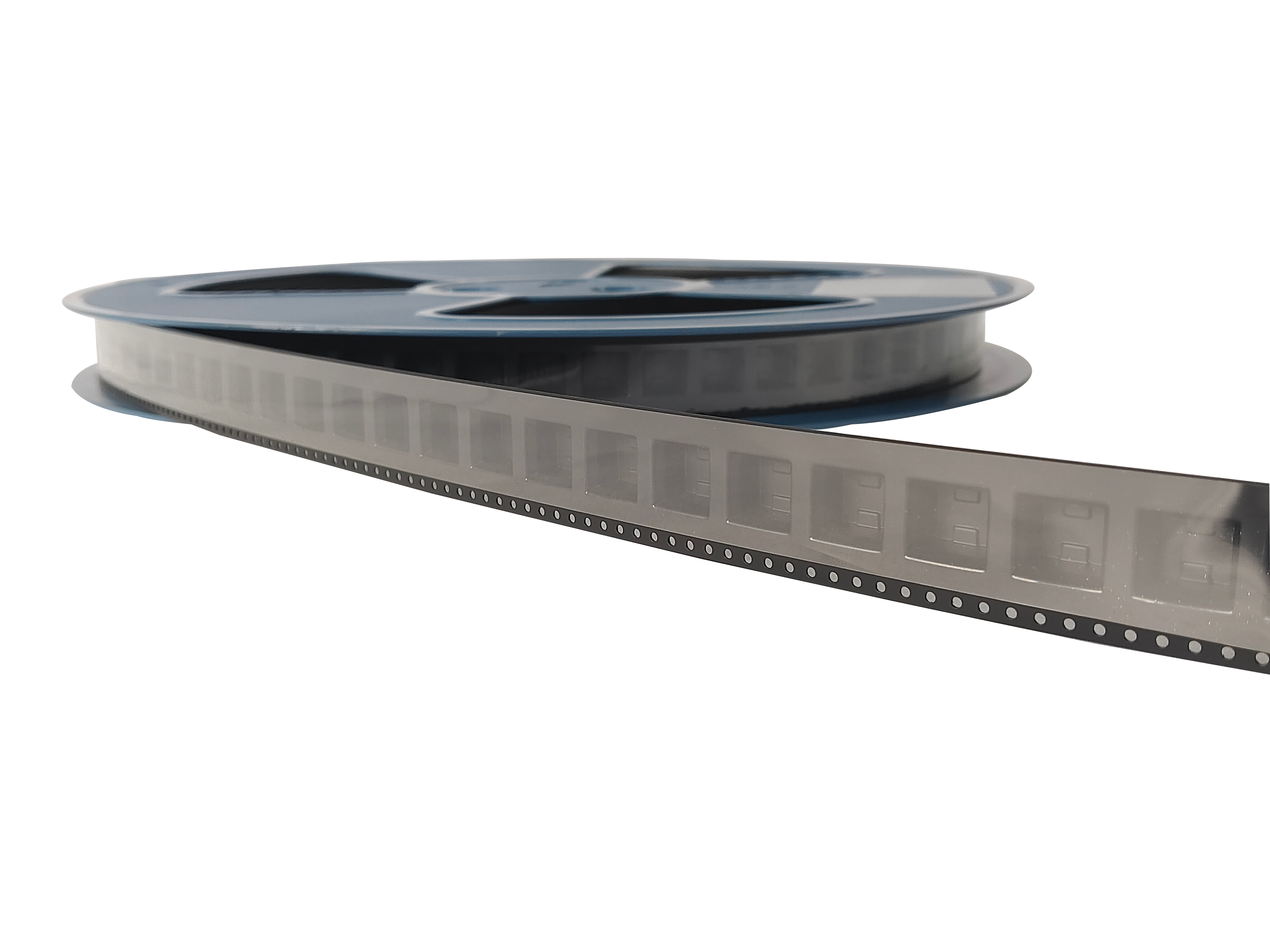

With the development of device sealing and loading process, more and more low-density water vapor permeability plastic materials are used in large quantities, the number of pins is becoming more and more dense, and moisture-sensitive device control technology is facing huge challenges. Device design requirements of high integration, production processing requirements of higher efficiency, making the vast majority of current devices have is surface mount packaging.

First, the electronic components of the environmental requirements

Electronic components must be stored in a clean, ventilated, non-corrosive gas warehouse class indoor environment, the warehouse should be in the channel open state. Another storage electronic components warehouse temperature and relative humidity must meet the following requirements: temperature: -5-30, relative humidity: 20%-75% RH, the warehouse environment temperature and humidity values will directly affect the storage life of electronic components and quality quality.

Second, the special requirements of electronic components

1. Electrostatic sensitive devices (such as MOS field effect transistors, GaAs field effect transistors, CMOS circuits, etc.) should be stored in storage equipment with shielding electrostatic effect.

2. Electronic components that are sensitive to magnetic fields but do not have their own magnetic shielding, should be stored in storage devices with shielding magnetic fields.

3. Electromechanical original parts with oil seal should be kept intact.

3. Electronic components to determine the limited storage period: the limited storage period of electronic components according to Appendix

Third, the limited storage period of electronic components

Different levels of electronic components stored in the appropriate temperature and humidity parameters are also different. A-level device storage temperature and humidity values: 15-25, 25%-60% RH; B-level device storage temperature and humidity values: -5-+30, 20%-75% RH; C-level device storage temperature and humidity values: -10-+40, 10%-80% RH.

Fourth, electronic components storage requirements

1. Electronic warehouse requires an anti-static floor, personnel must be in accordance with the requirements of anti-static, dressed in anti-static clothing, wearing anti-static bracelets.

2. Requirements according to the category of goods zoning storage, flammable and explosive products require appropriate isolation measures, for special requirements of the goods should have significant warning signs or safety signs.

3. Materials are neatly arranged, the contents of the stock card out and in are standardized, so that the accounts, materials and cards are consistent.

4. Items can not be stored directly on the ground, need to have a tray or shelf protection.

5. Material stacking requirements on the small under the large, light under the heavy, a tray can only be placed on the same material, stacking height has special requirements based on special requirements stacking, but the maximum shall not exceed 160cm.

6. Bulk materials, trays and items with special requirements are stored with specific reference to the relevant specifications.

7. For items with anti-static requirements, the following methods must be selected according to the actual situation: put in anti-static bags and anti-static moisture-proof cabinet storage, etc.

Fifth, electronic components of the raw material protection requirements

1. Electronic components should be fully considered the requirements of dust and moisture protection, etc.

2.For vacuum-packed PCB light board, IC, etc. to be packaged intact, can not let the copper foil and pins directly exposed to the air, to prevent product oxidation.

3. For the protection of special raw materials, please protect them according to their requirements.

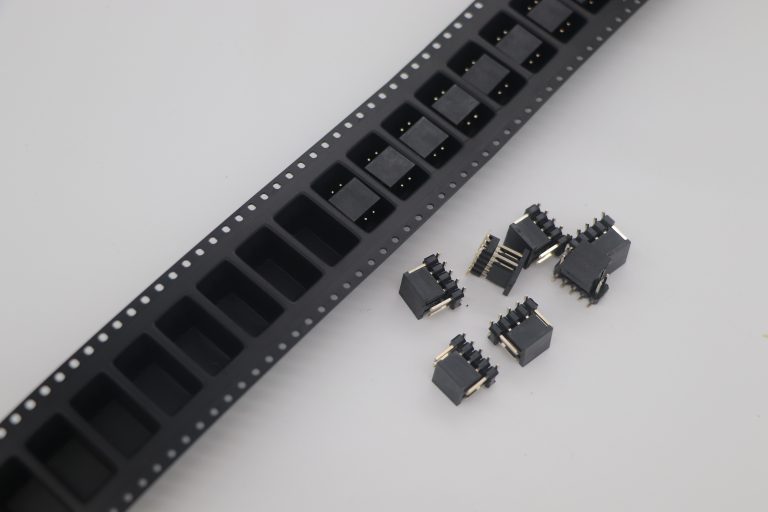

4. For components with pins, especially IC and other components with easily deformed pins should be packed in the original packaging form to avoid the deformation of the pins of the components resulting in inconvenience or even inability to work.

Storage of electronic components have strict requirements for environmental temperature and humidity parameters, such as:

(1) integrated circuit: moisture on the semiconductor industry is mainly in the moisture can be through the IC plastic package and from the pin and other gaps into the IC internal, resulting in IC moisture absorption phenomenon.

In the SMT process of the heating link to form water vapor, the resulting pressure leads to IC resin package cracking, and the internal metal oxidation of IC devices, resulting in product failure. In addition, when the device is soldered on the PCB board, the release of water vapor pressure will also lead to false soldering.

According to the IPC-M190 J-STD-033 standard, after exposure to high humidity air SMD components, they must be placed in a low humidity humidity cabinet below 10% RH humidity for 10 times the exposure time, in order to restore the components of the “workshop life”, so as to avoid scrap and ensure product quality.

(2) liquid crystal devices: LCD and other liquid crystal devices such as glass substrates and polarizers, filter lenses in the production process, although to be cleaned and dried, but to be cooled down will still be affected by moisture, reducing the product qualification rate. Therefore, after cleaning and drying, they should be stored in a dry environment below 40% RH.

(3) Other electronic components: capacitors, ceramic devices, connectors, switch parts, solder, PCB, crystals, silicon wafers, quartz oscillators, SMT adhesive, electrode material adhesives, electronic paste, high-brightness devices, etc., are subject to the hazards of moisture.

(4) Electronic devices in the process of operation: semi-finished products in the packaging to the next process, PCB packaging before and after the packaging to the power between, after unpacking but not yet used IC, BGA, PCB, etc.; waiting for the solder oven welding devices, baked devices to be returned to temperature, not yet packaged finished products, etc., are subject to the dangers of moisture.

(5) Finished electronic machine: in the storage process will also be subject to the hazards of moisture, such as storage in high humidity environment for too long, will lead to failure, for computer boards CPU, etc. will make the gold finger oxidation lead to poor contact failure.

In general, the preservation of electronic components is very important. Must be well packaged and away from high temperature, high humidity and chemical attack environment.