Contact Your NewwaySMTC Representative Now! [email protected]

The trend of carrier tape precision processing, the future demand of the market will steadily develop

According to the “Global and China Plastic Carrier tape Industry Market Status Analysis and Development Prospects Research Report” released by Lidl Industry Research Center, the main external development environment of China’s plastic carrier tape industry (policy impact, technology trends impact, etc.), the impact of upstream development of the plastic carrier tape industry chain, the current situation of the plastic carrier tape industry and market supply and demand.

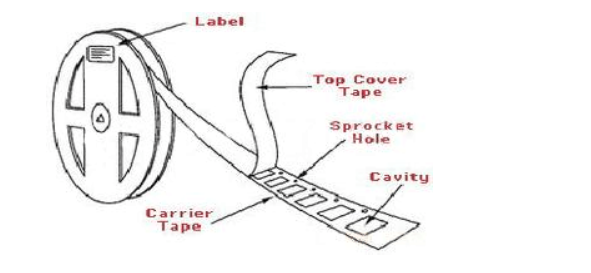

Carrier tape, i.e., a packaging for chip electronic components (also called SMT components).

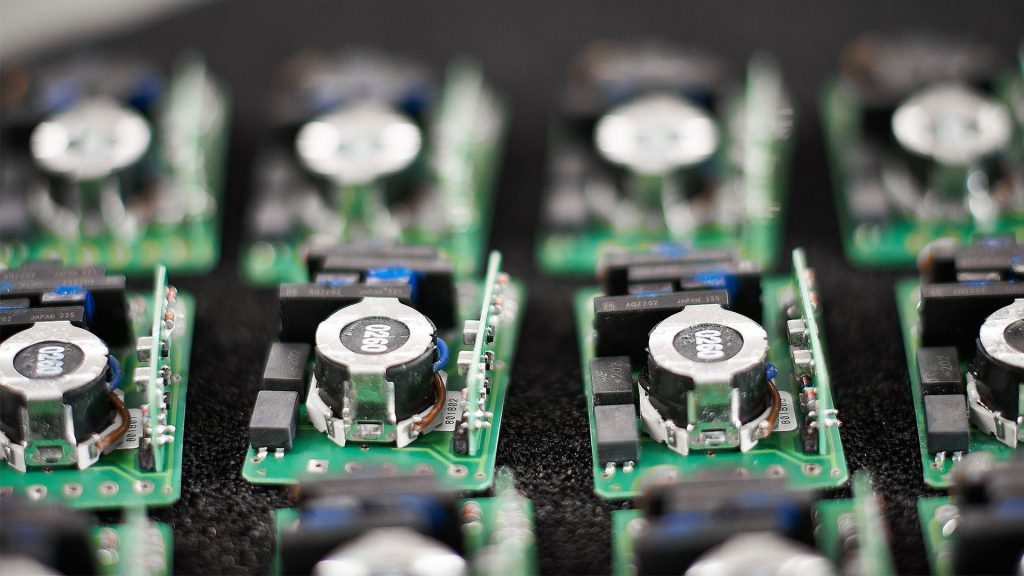

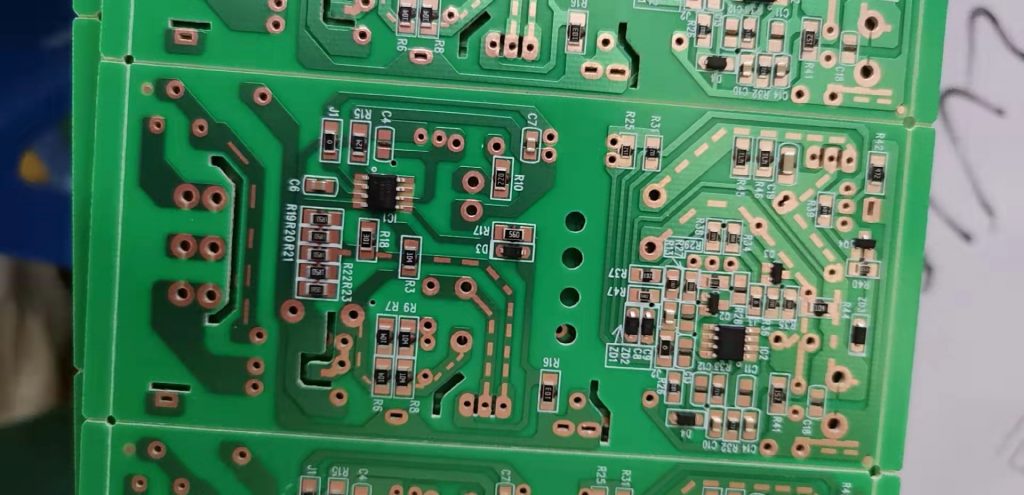

As the function of electronic equipment becomes more and more complex, the integration of electronic components requirements are also increasing, thus promoting the trend of miniaturization of electronic components packaging. SMT components, refer to the solder joints with completely no lead or lead very short components, that can be directly mounted on the PCB.

In the future, as the trend of miniaturization of components continues, the carrier tape is also developing towards the trend of precision and plasticization. The packaging of electronic components has been experienced two times from through hole cartridge (THT, Through HoleTechnology) to surface mount (SMT, SurfaceMount Technology). THT components, which are components with leaded solder joints, are mounted on PCBs with corresponding mounting holes and are soldered on the back side of PCBs after mounting. Since SMT components have significantly reduced solder joint pitch and diameter compared to THT components, they are significantly smaller and more integrated.

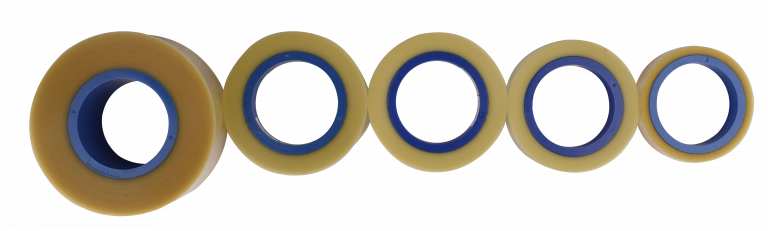

In addition to its plastic hardware manufacturing technology solutions, the most important product production is SMT consumables-related products, business started in 2000, and today we have a development, production, quality, sales, and after-sales service team, to provide customers with raw materials, carrier tape and reel design and development, manufacturing, automation equipment, the packaging on behalf of customers, and factory layout of the One-stop total solution and service. Our vision is to be the pioneer in the industry of electronic packaging materials and to continue to provide customers with value-for-money solutions and products and services.

THT

SMT

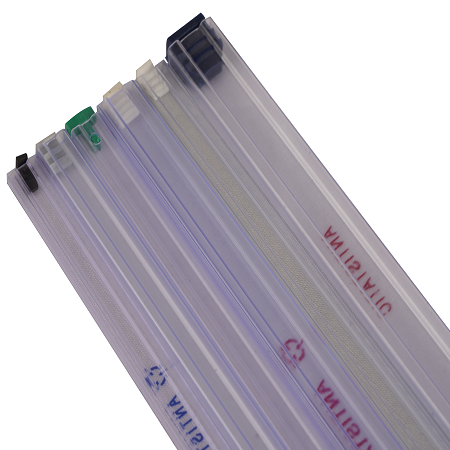

The carrier tape includes two categories: paper carrier tape and plastic carrier tape

The material of paper carrier tape determines that it can only be used for chip components with thickness less than 1mm (usually passive components), and chip components with thickness above 1mm can only be packaged by plastic carrier tape. Paper carrier tape can be divided into perforated paper tape and pressed paper tape, and plastic carrier tape can be divided into black plastic carrier tape and transparent plastic carrier tape. According to the performance, basically, black plastic carrier tape > transparent plastic carrier tape > perforated paper tape > perforated paper tape, the price is also in this order from high to low.